Holding It Together: Lessons in Book Binding

I left my last post about book production (before desktop publishing) with sheets of paper running through a printing press. Here we will look at how pages are bound in page order and held together in what we call a “book.”

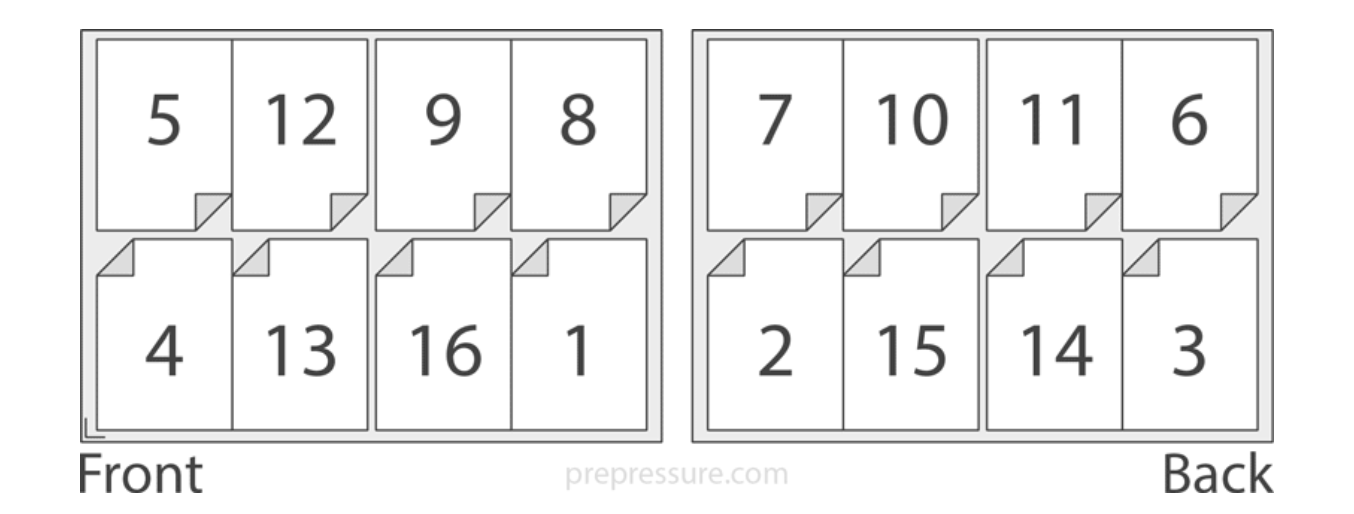

The large sheets of paper chosen for a sheet-fed press are of a size that allows a pre-determined number of the book-sized pages to fit on it. Traditional printing—using an offset press versus a digital process that utilizes an inkjet or laser printer—relies on multiples of four for setting up pages to go on press. Most books are arranged in sixteen-page signatures—a group of pages that will be folded and trimmed to make one section of a book.

There’s a little bit of magic in the folding of the large sheet of paper that emerges from the press with sixteen pages on it. It’s something called imposition: the arrangement of the sixteen pages on the one big sheet of paper in a way that allows simplicity in the folding stage and eliminates paper wastage.

When this one sheet of paper is precisely folded and trimmed, it will represent a signature with pages numbered “1” to “16.” If a book is “176 pages,” it contains eleven signatures.

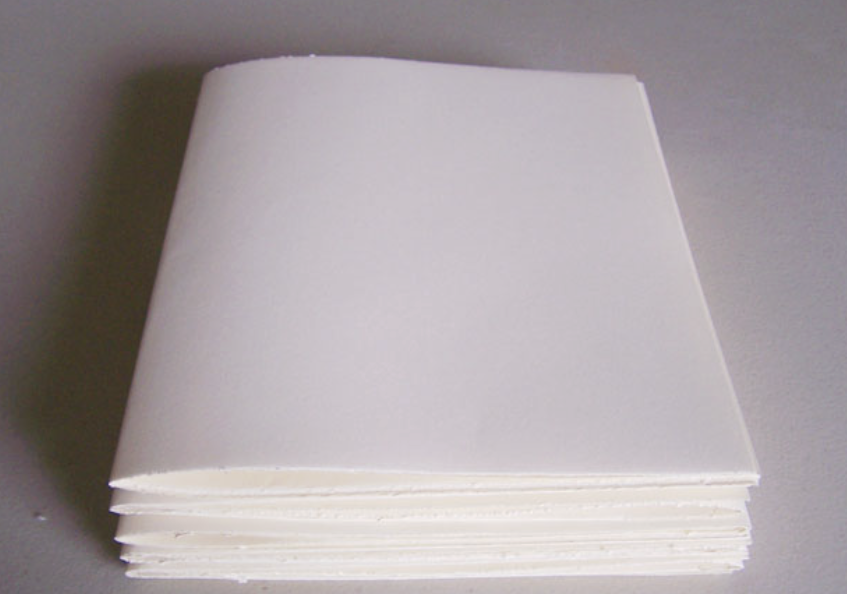

Once the pages are printed and grouped in sequential signatures, they are joined together in a text block.

There are a variety of methods for binding a text block. Here, I will only discuss casebound (hardcover) and paperback binding because they are the two methods Dirt Roads LLC most commonly offers.

Prior to printing, clients choose the binding format they prefer. The type of book going into production—color illustrated with photos throughout, unillustrated black-and-white text, or black-and-white text with inserts of color pages—will inform how the hardcover “case” or the paperback “cover” will be joined to the text block.

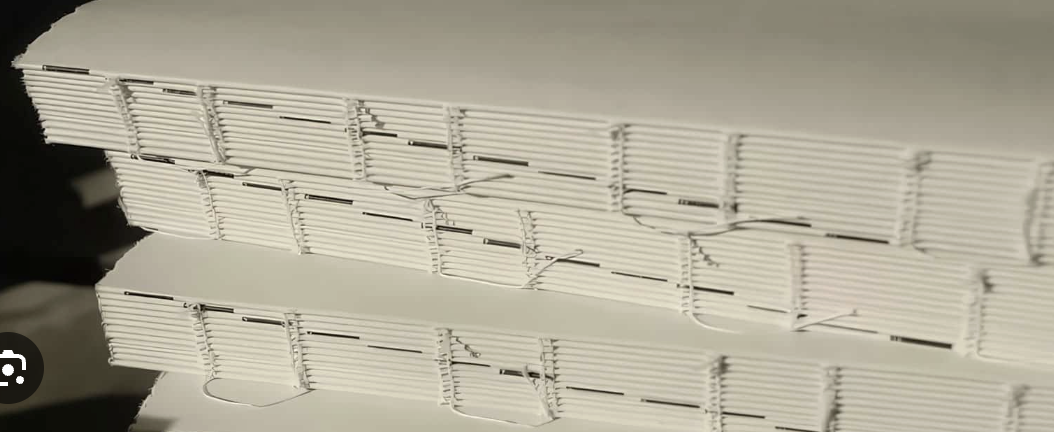

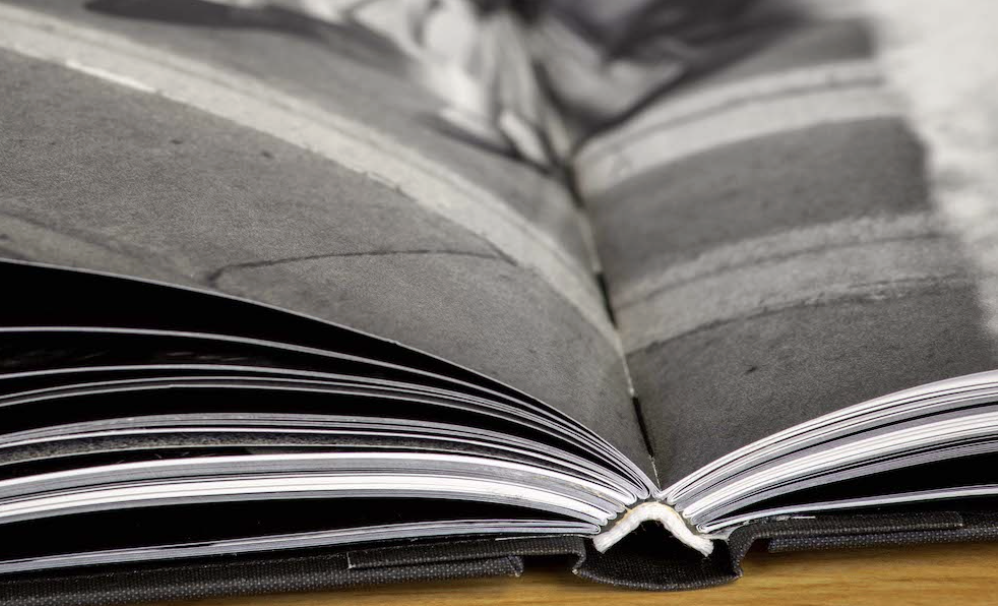

Full-color books produced by Dirt Roads LLC are primarily bound with a method called Smyth sewing. This is considered the strongest binding process since sturdy thread is used to actually “sew” the signatures together. This is particularly important for books comprised of heavier coated paper or books with a significantly high number of pages. Both casebound and paperbacks can be Smyth sewn.

The other common binding option is perfect, which employs glue rather than thread. This method is commonly used for paperbacks, especially those on uncoated, lighter-weight papers, and thinner books printed on coated paper. Compare the photo above, with sewn sections, to the one below, using glue.

This explanation is a very basic overview. There are many variations, depending on the printer, the printer’s specialty, and even the printer’s geographical location. If you are interested in book-making, I encourage you to take a deeper dive into the intricacies of the binding process via the many good resources to be found online.

—Martha